Ball-jointed dolls (BJDs) have existed for over a century, but they didn’t gain popularity outside Japan until the late 1990s. The German company Kammer & Reinhardt produced the first known BJD in 1909, but it wasn’t until the early 2000s that they took off as an art form and collector’s item. The modern-day BJD movement began in South Korea and Japan in the late 1990s.

(Image courtesy of dolkbjd)

Artists began creating their unique dolls using resin, allowing greater flexibility in posing and customization. Soon after, independent doll makers emerged worldwide who created their original designs.

Explanation of what BJD dolls are

BJD dolls are highly-articulated, poseable ball-jointed dolls made from special resin materials. They have an internal skeleton structure that allows them to be moved into any position without breaking or damaging the doll’s exterior appearance.

Connectors hold Their body parts together, allowing them to move freely. Despite being mass-produced today, each ball-jointed doll is unique.

Their skin tone, eye color and shape, hair color and style can be customized to fit a specific individual or character design. Many collectors enjoy making their clothing and accessories for their BJDs as well.

These handcrafted works of art are not just toys or playthings; they represent their creators’ high level of skill and craftsmanship. For many enthusiasts, owning a ball-jointed doll is like owning a piece of art – something to appreciate aesthetically and technically.

Materials Used

Types of Resin Used for the Doll’s Body and Head

(Image courtesy of dolkbjd)

Ball jointed dolls (BJDs) are typically made from a type of polyurethane resin called urethane resin. This resin is known for its durability, flexibility, and ability to hold intricate details. It is commonly used in the BJD manufacturing process due to its suitability for casting and molding purposes. Different manufacturers may use variations of urethane resin with specific formulations to achieve desired characteristics such as skin tone, translucency, or hardness.

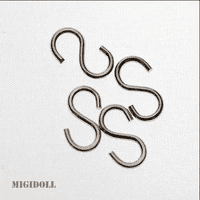

Different Types of Joints and Connectors Used for Articulation

(Image courtesy of dolkbjd)

Articulation is one of the most important features that sets BJD dolls apart from other types of dolls on the market today. For a BJD doll to have realistic movement capabilities, special joints and connectors need to be used.

The most common types of joints used in BJD dolls are ball joints. Ball joints provide a full range of motion with 360-degree rotation.

Connectors that hold these joints together can range from hooks attached to hands or fee to swiveling pieces that turn. Designers must take care when choosing which joint mechanisms will work best for their particular design so as not to limit or compromise on articulation possibilities while ensuring stability remains when posing the doll.

The Art of Sculpting BJD Dolls

(Image courtesy of dolkbjd)

Creating a BJD doll is truly an art form. The dolls are sculpted by hand by skilled artisans or designed digitally using 3D modelling software.

The sculpting process involves carefully crafting the shape and proportions of each body part to ensure the doll looks as realistic as possible. To create a lifelike appearance, artists must pay careful attention to the proportions and balance of each body part.

For example, the head should be proportionate to the body, and the limbs should be in proportion with each other. Small details like fingers and toes must be carefully shaped to look realistic.

This attention to detail sets BJD dolls apart from other types on the market. The importance of balance cannot be overstated when creating a realistic-looking BJD doll.

A properly balanced doll will stand independently without support, allowing for greater posing flexibility. This balance is achieved through careful consideration of weight distribution throughout the body.

Some artists will even add weights inside the doll’s feet or torso to help achieve perfect balance. Sculpting a BJD doll truly requires not only artistic talent but also technical know-how in order to create a high-quality product that collectors will love for years to come.

Mold Making

Creation of silicone molds from the original sculpt

After the sculpting process is complete, the next step in creating a BJD doll is to make a mold of the original sculpt using silicone. The sculpt is carefully cleaned and prepared for molding. Then, a silicone mixture is poured over the entire surface of the sculpt to capture all of its details and texture.

Once it has cured, the mold can be removed from the original sculpt. Creating a good mold is crucial to ensure the high-quality production of BJD dolls.

Any imperfections or bubbles in the mold can affect the final product’s quality and accuracy of the original design. That’s why professional BJD doll makers often use multiple molds for each part of their design, ensuring consistent quality across all their dolls.

Casting process using resin to create the final product

After creating a high-quality mold, it’s time for casting – pouring resin into molds to create doll parts. Resin is chosen because it allows for great detail and coloration options while being durable enough for everyday use.

The first step in this process involves cleaning and preparing each mold before pouring in pigmented resin material. After pouring into a specific size range, they are left alone to set overnight or longer until fully cured.

Once ready, each part can be removed from its respective mold with care so as not to damage any fine features or details captured during casting—for instance, the hands’ delicate fingers or knees’ contour lines. After examining each piece for any flaws or defects (which might require additional finishing touches), all parts are assembled by attaching different joints like head-neck connectors or elbow-knee connectors closely fitting as well as possible before continuing on to customizing or dressing.

Assembly: Bringing the Doll to Life

(Image courtesy of dolkbjd)

The assembly process is one of the final steps in creating a BJD doll. This is where all the individual parts of the doll come together to form a complete, articulated figure. Artists will use elastic cord to string it through the body and then attach the ends to s-hooks at the hands, feet, and head.

These connectors, s-hooks, and elastic, allow for a wide range of movement and flexibility in the doll’s limbs and neck. Next, eyes are carefully inserted into their sockets, typically with a small amount of putty to hold them in place.

Once the joints and eyes are securely in place, it’s time to add personality to the doll with its wig and clothing. BJD dolls often come bald with no hair, so adding a wig can be an exciting step that brings your doll to life.

Wigs can be made mostly from synthetic materials, and come in a wide variety so selecting one depends on personal preference and budget. Clothing options for BJD dolls vary widely – some collectors prefer to create their own outfits or commission custom pieces from independent designers. In contrast, others purchase pre-made clothing sets from manufacturers.

Painting: Adding Realistic Details

The final step in creating a BJD doll is adding paint details such as eyebrows, eyelashes, and blush. This step requires skillful hand-painting techniques that can bring out your doll’s unique features and facial expressions.

Various paints can be used for this process, including acrylics or water colored pencils/paints. Base colors and minor details like eyebrows can be painted first. Eyebrows are generally painted on first using small strokes that mimic real eyebrow hairs.

Eyelashes can be applied using trimmed fake eyelashes found at beauty stores. Using shaved down chalk pastel into a powder can be applied to appear as blush to give your BJD doll that youthful glow.

By taking care during the assembly and painting stages, you’ll have created an amazing piece of art that is truly unique. Your BJD doll will look stunning and ready to be displayed in your home for others to enjoy.

Customization Options

Different skin tones available

One of the most exciting aspects of BJD dolls is the wide variety of customization options available to collectors. One of the key aspects of customization is the availability of dolls in various skin tones.

Unlike many other types of dolls, which are typically only available in a limited range of colors, BJD dolls come in a rainbow of hues, from pale white to deep ebony and everything in between. This allows collectors to create dolls that look like themselves or their loved ones and explore different cultural aesthetics and styles.

Various eye shapes, colors, and designs

Another area where BJD dolls can be customized is their eyes. Eyes are often considered the “windows to the soul,” and they play an important role in giving a doll its character and personality. BJD doll eyes come in a variety of shapes, sizes, colors, and designs.

The eyes can be made from acrylic, glass, and even urethane.

Possibility for customized clothing and accessories

One unique aspect of BJD doll customization is the ability to create custom clothing and accessories for your doll. Since each doll has its unique size and shape, it can be challenging to find clothes that fit properly “off-the-rack”.

However, many collectors enjoy creating clothing designs or commissioning outfits from talented seamstresses or tailors within the community. This allows them to create truly one-of-a-kind wardrobes for their beloved dolls.

Similarly, accessories such as shoes, hats, jewelry, and even props like miniature books or musical instruments can be crafted by hand or purchased from specialty shops catering to BJD dolls. The possibilities for customization are endless, making each doll a unique work of art.

Conclusion

After reading about the intricate process of creating BJD dolls, it’s easy to see why they are so highly valued by collectors and enthusiasts alike. The amount of time and attention to detail put into each doll is commendable. Every step, from the sculpting process to the final assembly, is carefully executed to ensure the finished product is a work of art.

BJD dolls are created using high-quality resin materials that allow for a wide range of customization options. Sculpting involves creating an original design by hand or through 3D printing.

From there, silicone molds are made and used to cast the final product in resin. Joints, s-hooks, and connectors are then attached for articulation, eyes and wigs are added for realism, and painting is done to add details such as eyelashes and eyebrows.

One of BJD dolls’ most exciting aspects is their endless customization potential. With different skin tones available, eye shapes and colors, clothing options, and accessories, collectors can create their one-of-a-kind doll that perfectly suits their tastes.

Whether you’re a serious collector or just someone who appreciates beautiful craftsmanship, there’s no denying that BJD dolls are truly special works of art. Learning about how BJD dolls are made has given us a new appreciation for these stunning creations.

Each doll represents countless hours of hard work and dedication from skilled artists worldwide. We hope this article has inspired you to learn more about these fascinating objects or even consider starting your own collection!

Learn more about BJD sculpts and see some amazing interviews with BJD artists on my YouTube channel!

Recent Posts

Come join my BJD Newsletter where you will learn about new dolls coming out, BJD doll sales, and artist highlights! There will also be other BJD goodies just for you!

When to Restring: Recognizing Signs Your BJD Needs a Tune-Up

Learn how to recognize signs your BJD needs a tune-up and restringing process. Maintain your doll's stringing for longer life with this step-by-step guide.